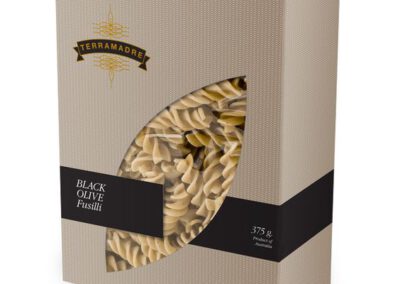

Printed packaging

To create an exclusive package, to grab attention and encourage the purchase of your product, it is worth using a variety of packaging decoration elements.

Foiling

Foiling – covering part of the material (paper, cardboard, plastic, leather, imitation wood) with foil.

The purpose of foiling is to give the product the impression of a metalized surface and luxury.

EQUIPMENT AND FORMATS:

- format of small and small editions (100 mm x 100 mm);

- format of large and large works (1260 mm x 850 mm);

- format of large and continuous works (210 mm x 300 mm).

Foil is most commonly used to highlight print elements on book and magazine covers, packaging, business cards, labels, diplomas, binders and folders, and flyers.

UV varnishing

UV varnishing is a technology where the sheet or part of it is coated with UV varnish. Varnish can give the paper the impression of softness, roughness, shine.

With automatic varnishing technology we can varnish paper up to 300 gsm (grammar) thick, and with non-automatic varnishing, we can varnish up to 10 mm thick.

We can varnish on paper, cardboard, corrugated cardboard, plastic, organic glass, hard binding covers, material-covered covers.

We provide structural, relief (3D), and micro varnishing services.

EQUIPMENT AND FORMATS:

▸ we perform small and complex orders with semi-automatic machines (100 mm x 210 mm);

▸ we print large editions, simple jobs with high-speed equipment (1040 mm x 740 mm).

Die-Cutting

Cutting is the process by which a sheet, cardboard, or plastic is cut according to the shape of the pick. Materials to be cut: paper, cardboard, corrugated cardboard, plastic, leather, rubber, felt, foam, various synthetic fabrics, cork, and other similar materials.

EQUIPMENT AND FORMATS:

▸ cutting of small and medium cutting runs (1020 mm x 720 mm);

▸ cutting of thick binding laminated cardboard up to (1020 mm x 720 mm);

▸ cutting out larger editions from 2000 sheets (700 mm x 500 mm);

▸ cutting large editions from 2000 to 5000 leaves (1260 mm x 850 mm).

Cutting is most commonly used in order to create a form for a future packaging (perimeter cutting) or to add design for the packaging by removing elements from the surface.

Screen printing

Screen printing is the most popular stencil printing technique. Silkscreen prints can be placed on any surface of paper and fabric, plastic, wood, glass.

EQUIPMENT AND FORMATS:

▸ orders from (100 mm x 210 mm) we perform with semi-automatic machines;

Screen printing is used for creating packaging, book covers, business cards, bags, wooden decorations and other.

Kiss-Cutting

Kiss-Cutting is the process during which light cuts within the border of your cardboard or paper is performed while the background material stays intact. Such technique is used for production of stickers.

EQUIPMENT AND FORMATS:

▸ crossing small and medium editions by hand (50 mm x 90 mm);

▸ cutting out larger editions from 2000 sheets (700 mm x 500 mm);

Emboss

Emboss is a printing technology in which a printing cliché is made on paper or cardboard according to the desired design, thus leaving a rise on the right side of the paper.

EQUIPMENT AND FORMATS:

▸ we perform small and complex orders with semi-automatic machines (50 mm x 90 mm)

▸ we print large, simple orders with high-speed equipment (1260 mm x 850 mm).

Lamination

Lamination is the process by which paper or board is laminated. We can do hot or cold lamination. Paper or cardboard coated with laminate can acquire the following effects: softness, gloss, roughness.

EQUIPMENT AND FORMATS:

▸ we perform all orders with high-speed equipment (780 mm x 1100 mm).

Interested? Let's talk

If you want to know more about the process, priceses or results, write us a message and we will reach you as soon as possible!

Contacts

JSC Tygelis Pakuoja

Your company’s packaging management partner

VAT number: LT100011083218

Company code: 304581246

Address: Sandėlių str. 36 str.,

Vilnius, Lithuania

2021 © Tygelis Pakuoja